Integrated Computational Engineering and Materials Design Division

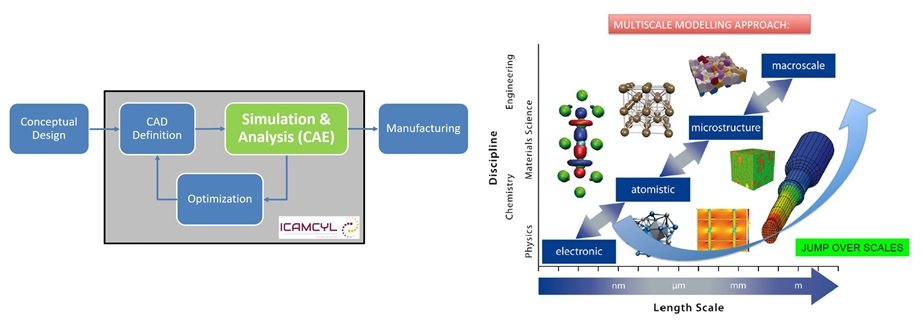

The Integrated Computational Engineering & Materials Design Division focuses its activities in Computational Multiphysics Modelling:

- Computational Fluid Dynamics (CFD)

- Computational Structure Analysis (CSA)

- Multiscale Materials Modelling

- Computational Materials Discovery

- Data analytics, machine learning, statistical prediction, topology optimisation…

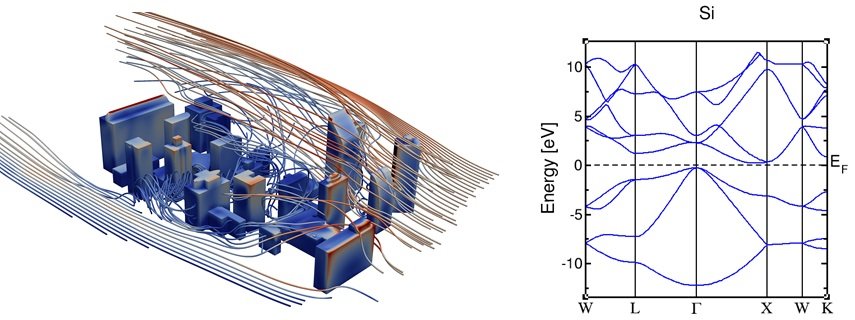

Computational Fluid Dynamics (CFD) for industrial flow problems

ICAMCyL provides state-of-the-art modelling services that support the aerothermodynamic design and optimization processes of components for several industries: aerospace, turbomachinery and propulsion, energy, automotive and transportation, marine, and many others. The Foundation offers also wide numerical modelling activities related with atmospheric flows and wind environments: wind environments in cities, dispersions of pollutants, natural ventilation areas, …ICAMCyL can also produce high-fidelity CFD datasets aiming at supporting validation of wind-tunnels or flight-test results, and perform deep studies about CFD sensitivities, mesh dependency and influence of physical modelling

Finite Element Analysis of structures and materials

We offer modelling capabilities in the field of CSA. Static, dynamic, or modal FEA can be employed to evaluate mechanical stresses, deformations, vibrations and fatigue of solid parts, to perform thermal analysis of the materials, and to simulate complex impact conditions.

Multiscale materials modelling

The capabilities of ICAMCyL include multiscale modelling of materials, covering all the range from the nano- to the macro-scale. This is a fundamental tool to accelerate innovation, discovery and insertion of new materials, and can suppose an effective way to achieve cost reductions and to optimize products and processes. This approach can be applied to all kind of materials: polymers and composites, metals and alloys, batteries, fuel cells, catalyst and much more!

Computational Materials Discovery

Instead of conventional trial-error method historically employed for the discovery of new materials, last advances in computational science allow the use of solid state matter theory in the prediction of new materials with tailored properties. Furthermore, it is possible to use computational power to screen broad databases experimentally or computationally generated to look for relevant properties with the help of advanced techniques in data analysis and machine learning. Data analytics, machine learning, statistical prediction, topology optimization…ICAMCyL is able to provide counselling in the application of the most cutting-edge techniques applied to the data analysis of all kind of industrial applications, as predictive maintenance, monitoring and diagnostic, computer vision and much more!

CONTACT INTEGRATED COMPUTATIONAL ENGINEERING AND MATERIALS DESIGN DIVISION:

Telephone: (+34) 987 440 481

E-mail: engineering(at)icamcyl.com